Rig Manufacturing has designed and engineered our own in house BOP Lifting Ring frame that is manufactured for many different working load limits. These BOP Lifting Ring frames are a safe and in-expensive way for rigs to add easier ways for handling and installing their BOP stack on each well. Our design prevents you from having to modify your BOP stack to accommodate a complete BOP stack lift on to the well. It is designed to fit around under your annular and lift the BOP stack without having to attach or weld anything to the BOP stack. Once the BOP stack is installed on the wellhead the BOP lifting frame can also be used as a secondary safety tieback anchor for the BOP stack.

- BOP Lifting Safety Increased (Main Frame lifting lugs are rated for the complete stack)

- In-Expensive (Much cheaper than other BOP handling devices)

- Convenient (Can add to any BOP stack and stay on stack while drilling)

- Size (Much smaller design than older style frames)

Typical standard BOP sizes we design and manufacture are below. We can design and customize the lifting frame to your custom requirements if needed.

11″ 3M RX-53 Flange Size (21-1/2″ DIA)

11″ 5M RX-54 Flange Size (23″ DIA)

11″ 10M BX-158 Flange Size (25-3/4″ DIA)

13-5/8″ 5M BX-160 Flange Size (26-1/2″ DIA)

13-5/8″ 10M BX-159 Flange Size (30-1/4″ DIA)

16-3/4″ 5M BX-162 Flange Size (30-3/8″ DIA)

16-3/4″ 10M BX-162 Flange Size (34-5/16″ DIA)

18-3/4″ 10M BX-164 Flange Size (40-15/16″ DIA)

18-3/4″ 15M BX-164 Flange Size (45-3/4″ DIA)

20-3/4″ 3M R-74 Flange Size (33-3/4″ DIA)

21-1/4″ 2M R-73 Flange Size (32″ DIA)

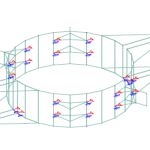

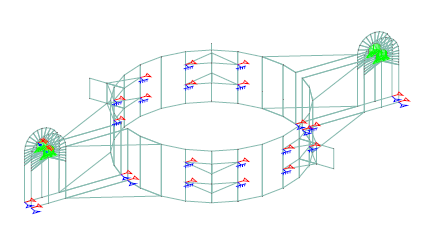

These BOP Lifting frames are engineered with a 2.0 DAF (Dynamic Amplification Factor). The BOP Lifting frame is a two-piece frame that will wrap around the BOP stack assembly under the annular around the bottom flange area supporting the complete stack during a lift. Two lifting lugs located at 180 degrees from each other are used to connect to BOP lifting hoists. We can also install four (4) centering lugs for Offshore applications if needed to help center the stack.

The assemblies are pull tested for more than their WLL and Mag partical weld tested after. These pull tests and NDT reports will be included in the RMC data book along with MTR’s. These data books will also include FEA Animation (Stress/Strain) Analysis performed by a Structual P.E. Engineer.